cx.Link – Autonomous Construction Machines and Humans

During the 2015/2016 academic year three BTH students have been collaborating with three students from Stanford University‘s ME310 Global Design Course. Project sponsor has been Volvo Construction Equipment. The project has focused on building trust between autonomous construction machines and humans in construction sites.

Contents

About the project

Project website: htttp://www.me310volvoce2016.com

Courses: ME310 (Stanford), TE2501 (MSc thesis), MT1441 (Innovation project), MT1480 (Innovation project, implementation)

Students:

Stanford ME310: Sam Frishman, Qinye Alsa Liu, Xiang “Alvin” Zhang

BTH (MSPI / MEch Engn): Hillevi Hallberg Lyggemark, Ryan Ruvald, David Winqvist

Project prompt

The students were tasked with a rather open prompt. They should explore and design solutions for a context where autonomous construction machines collaborate with humans in a construction site. To make this collaboration effective and efficient, several factors relating to trust and communication should be incorporated.

cx.Link

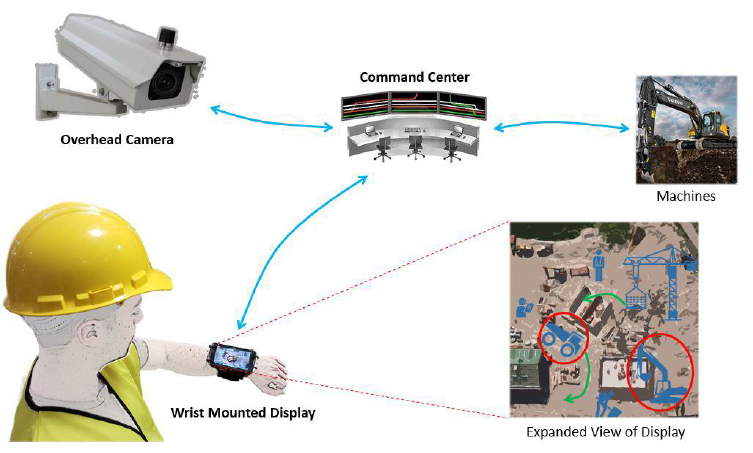

The cx.Link is a concept to support autonomous construction vehicles operating alongside human workers on major construction sites. The system contains a command center, a pod with a beacon light on each construction machine, a wrist mounted display, and a hardhat. In concert they work to enhance communication and thus trust in construction sites. The vision is

Below follows some descriptions of the parts.

The command center

The command center is the brain and processing unity of the system. It receives a bird’s-eye view of the construction site from an overhead camera. This is combined with information about machine and worker positions. This information is communicated to the other parts of the system and is made available when needed. When needed it can, for instance, alert a worker of an imminent danger.

The machine pod

Each autonomous construction vehicle is fitted with a machine pod. The pod features a signal light, which communicates with workers on the construction site. Here, function and status of the machine is stated so that the user can see that it is operational.

The wrist-mounted display

Each worker will have some additional personal equipment, which will provide them with added capabilities for communication and increased safety. The wrist-mounted display is implemented on a smartphone with a wrist mount. It displays information for the worker. Additionally, it provides wireless connectivity and GPS positioning.

The hardhat

In all constructions sites, the hardhat is a mandatory personal equipment for all construction workers. In the cx.Link concept, the hardhat is fitted with additional functionality. It is fitted with a bone conduction headset and led lights for alerting the worker of danger, system functionality, and machine intent. Depending on the specific situation, the system will provide workers with relevant information to enable them to take appropriate action.

As a leader in the construction industry, Volvo Construction Equipment are exploring concepts for running fully autonomous construction machines in aiming to increase productivity and to enhance safety for people in the sites. Even in this scenario there will be people on the site, maintaining machines and leading the operations. Therefore, the aim of the project is to create a system that will enable efficient communication between human workers and automated machines. Such a system will increase safety and foster trust between the human workers and machines.

More information

Find more information about this year’s project here:

- cx.Link for Volvo CE delivered at Stanford EXPE

- Stanford ME310 at BTH and Volvo CE

- EXPE 2016 at Stanford coming up

- “Dancing with ambiguity” in global Stanford/BTH/Volvo innovation project

- Human-machine interaction in autonomous mode

Find more information about previous years’ ME310 projects on these links:

- ME310 2015-2016: Human-Autonomous Machine Interaction

- ME310 2014-2015: Urban Mining

- ME310 2013-2014: Urban Mining

- ME310 2012-2013: Idéum

- ME310 related on our web

For more information, contact Christian Johansson (christian.m.johansson@bth.se) or Prof Tobias Larsson (tobias.larsson@bth.se).